chevaliernoir

Member

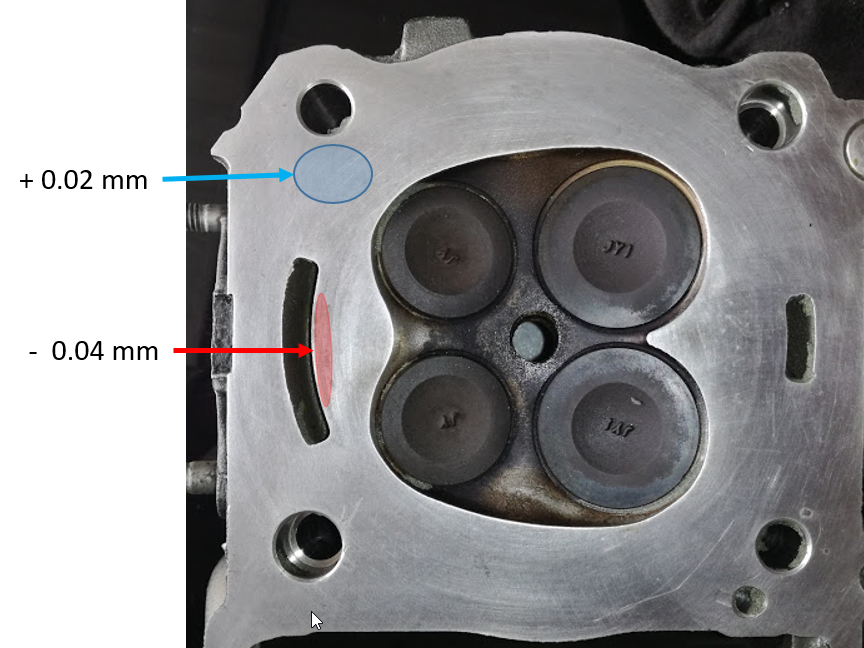

Today; I took engine head and cylinder at work to measure how flat is the gasket surface.

That was interesting. KTM write that the maximum allowable flatness deviation (sorry, I do not know the exact wording, but I'm quite sure it is understandable)

is 0.1 mm on the cylinder head, and also 0.1 mm on the cylinder.

I checked first the cylinder head.

I found that it's quite flat except a kind of "hole" of 0.04 mm deep, exactly where was the leakage, a a kind a "bump" of 0.02 mm nearby.

So flatness is 0.06 mm wish is considered acceptable by KTM, but the relation with my head gasket blown is quite obvious at is was less pressure on that area.

The cylinder side was better with a flatness around 0.02 mm

So my understanding is that the issue does not really come from the gasket (even if I imagine there are many different qualities) but the cylinder head flatness.

Thin gasket would not solve it.

So I decided to make it flat by myself (It is the first time I do this for a cylinder head)

I install grinding paper on a glass table (to be sure it is well flat, and spend time in moving the cylinder head on this making "8" movements... during a long long time..

[video]

[/video]

By the way, I finally decided to start by "500" paper in order to really remove material, then "800", then "1000" then "2000" then "5000" to have a mirror state.

Tomorrow, I will measure again the flatness, and see how it is improved or not.

That was interesting. KTM write that the maximum allowable flatness deviation (sorry, I do not know the exact wording, but I'm quite sure it is understandable)

is 0.1 mm on the cylinder head, and also 0.1 mm on the cylinder.

I checked first the cylinder head.

I found that it's quite flat except a kind of "hole" of 0.04 mm deep, exactly where was the leakage, a a kind a "bump" of 0.02 mm nearby.

So flatness is 0.06 mm wish is considered acceptable by KTM, but the relation with my head gasket blown is quite obvious at is was less pressure on that area.

The cylinder side was better with a flatness around 0.02 mm

So my understanding is that the issue does not really come from the gasket (even if I imagine there are many different qualities) but the cylinder head flatness.

Thin gasket would not solve it.

So I decided to make it flat by myself (It is the first time I do this for a cylinder head)

I install grinding paper on a glass table (to be sure it is well flat, and spend time in moving the cylinder head on this making "8" movements... during a long long time..

[video]

By the way, I finally decided to start by "500" paper in order to really remove material, then "800", then "1000" then "2000" then "5000" to have a mirror state.

Tomorrow, I will measure again the flatness, and see how it is improved or not.

Last edited: